One of the most essential makers in the industry is the press brake when it comes to metal manufacture. A press brake is utilized to shape and flex metal sheets into different forms and angles, making it indispensable in making markets such as automotive, aerospace, and building. From small workshops to huge manufacturing plants, the adaptability and efficiency of press brakes have made them a staple in modern-day metalworking environments. Amongst the numerous setups offered, the CNC press brake stands apart, as it uses sophisticated automation and accuracy, dramatically boosting productivity and precision. This blog site post will look into various elements of press brakes, including their kinds, vital features, and the significance of trustworthy makers like WEIYA, as well as the wider range of shearing machines utilized in metal construction.

China has emerged as a leading hub for press brake producers, providing a series of machines designed to satisfy the diverse needs of the metalworking industry. Firms such as WEIYA go to the leading edge of this industry, providing a broad array of hydraulic press brakes, electric press brakes, and CNC press brakes. These machines are made with advanced modern technology and innovative engineering to make certain high efficiency and dependability in demanding manufacturing atmospheres. Hydraulic press brakes, for example, are known for their immense power and ability to manage thicker products, making them suitable for durable applications. On the various other hand, electric press brakes are lauded for their power effectiveness and lower operating expense, which attract businesses concentrated on decreasing their carbon impact.

One can not neglect the relevance of shearing devices in metalworking along with press brakes. Shearing devices are crucial for cutting metal sheets and plates with precision and speed. 2 common kinds of shearing machines are the swing beam shearing machine and the guillotine shearing machine. The swing beam style enables the reliable cutting of thicker materials, while the guillotine type is better fit for straight cuts along the sides of thin sheets. Both equipments play an important function in preparing metal sheets prior to they are refined with a press brake, making sure that the first cutting satisfies the specified requirements for succeeding flexing operations.

The flexibility of CNC makers extends beyond press brakes to include numerous other kinds of metal cutting tools. CNC (computer numerical control) technology enables the automation of highly accurate tasks, making it simpler to create repeatable outcomes that meet rigorous top quality criteria. For larger operations, having a tandem press brake can use a number of benefits, enabling suppliers to deal with longer sheets of metal and enhancing general performance via continual procedure. Similarly, big press brakes bring added abilities to the floor, making them ideal for taking care of larger parts frequently found in industrial applications.

These equipments integrate the power of hydraulic press brakes with the accuracy of electric ones, supplying a hybrid technique that maximizes efficiency, minimizes power usage, and minimizes wear and tear on components. The choice of a press brake, whether it be hydraulic, electric, or a more sophisticated CNC version, usually pivots on the certain application and the kind of materials being processed.

In circumstances where firms are seeking to cut costs without endangering top quality, an NC press brake can be a feasible choice. While NC models might not use the same level of automation as their CNC equivalents, they still supply trustworthy performance for many standard applications. Nonetheless, for makers that prioritize high precision and automation, purchasing a CNC press brake is commonly the finest choice, specifically as the competitiveness of the production market becomes extra noticable.

Companies like Amada, Trumpf, YAWEI, and WEIYA have developed themselves as leaders in the press brake making room in China and past. The dedication to Shearing Machine quality and performance by these producers provides clients the assurance that they are spending in machinery that can withstand the rigors of daily use while providing the precision required for effective metal manufacture.

As sectors progress, so do the technical developments within the realm of press brakes. Features like the E21 press brake control system are becoming significantly usual, offering instinctive procedure and boosted programming capabilities, which subsequently minimize configuration times and boost performance. These improvements also facilitate less complicated driver training, allowing brand-new personnel to become skillful with machine procedures much more promptly, consequently enhancing the firm's overall result and performance.

Additionally, financial investments in modern press brake technologies expand beyond simply the devices themselves. Assimilation with clever manufacturing options, such as the Internet of Things (IoT), enables real-time surveillance, predictive upkeep, and understandings into operational effectiveness. This connection allows makers to maximize production timetables, anticipate machine downtime, and make data-driven decisions that straighten with business goals.

Generally, the globe of press brakes and shearing machines is both complex and huge, driven by innovation and demand for top quality. Each machine plays an essential function in metal manufacture, from first cutting to final shaping. With a wide range of options offered, makers have to carefully consider their specific needs-- whether they require an easy NC press brake or a sophisticated CNC design integrated into a broader smart manufacturing framework.

As a CNC machine tool factory, WEIYA specializes in a selection of devices, yet its press brakes stand out for their ingenious attributes and user-friendly procedures. No matter of whether one is in demand of a hydraulic press brake or an electric press brake, producers such as WEIYA aim to offer choices that incorporate efficiency with accuracy.

CNC press brakes are especially prominent among manufacturers looking for automation and advanced control attributes. The assimilation of CNC technology into press brakes indicates that drivers can input precise dimensions and specifications, enabling exact and repeatable flexing procedures. This tech-forward approach decreases the moment and labor needed for complex projects, considerably improving efficiency. While hydraulic press brakes remain to control the marketplace, servo and electric motor press brakes are additionally obtaining grip as a result of their reduced power usage and minimized functional expenses.

Shearing devices, including swing beam shearing machines and guillotine shearing equipments, are usually utilized together with press brakes in metal construction facilities. These equipments are created for cutting metal sheets with precision, functioning as a functional option for producers requiring complex and constant cuts. When integrated with a press brake, they form an effective duo vital for transforming raw metal right into finished parts.

Within the realm of metal cutting, QC12K swing beam shearing equipments have actually become a staple as a result of their robustness and performance. These devices are made to deal with numerous kinds of products, offering drivers with the flexibility required in a competitive production environment. The combination of a high-quality shearing machine and a trustworthy press brake allows makers to simplify their production and deal higher-quality items at a competitive cost factor.

For those interested in massive procedures, tandem press brakes are a perfect option. These equipments enable the processing of bigger sheets of metal while keeping regular bending accuracy. Furthermore, big press brakes frequently include boosted attributes that facilitate safer and much more effective procedures. Such developments in the market indicate the continual evolution of these devices, ensuring they satisfy the demands of contemporary manufacturing.

Torsion press brakes have likewise obtained focus for their special style and performance, particularly when it concerns bending thicker materials with accuracy. The torsion device enables versatility in the bending procedure, making it much easier to accomplish complex bends without misshaping the product. Meanwhile, NC (Numerical Control) press brakes streamline the procedure even more, making them an accessible option for workshops wanting to enhance their abilities without requiring considerable experience.

In verdict, as suppliers proceed to press for boosted performance and performance in metal construction, the relevance of top notch press brakes and shearing makers can not be overemphasized. The journey of changing raw metal right into practical elements through press brakes and shearing machines illustrates the impressive workmanship and technical expertise that specify contemporary manufacturing.

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Romeo Miller Then & Now!

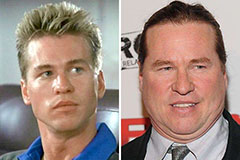

Romeo Miller Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!